Carbon Steel Double Deck Floor Scale

QC Weighing

Carbon Steel

0.8X0.8M~2X3M(or customized)

0.5T~10T

| Availability: | |

|---|---|

Are you looking for a robust, accurate, and easy-to-use weighing solution for your industrial or commercial needs?

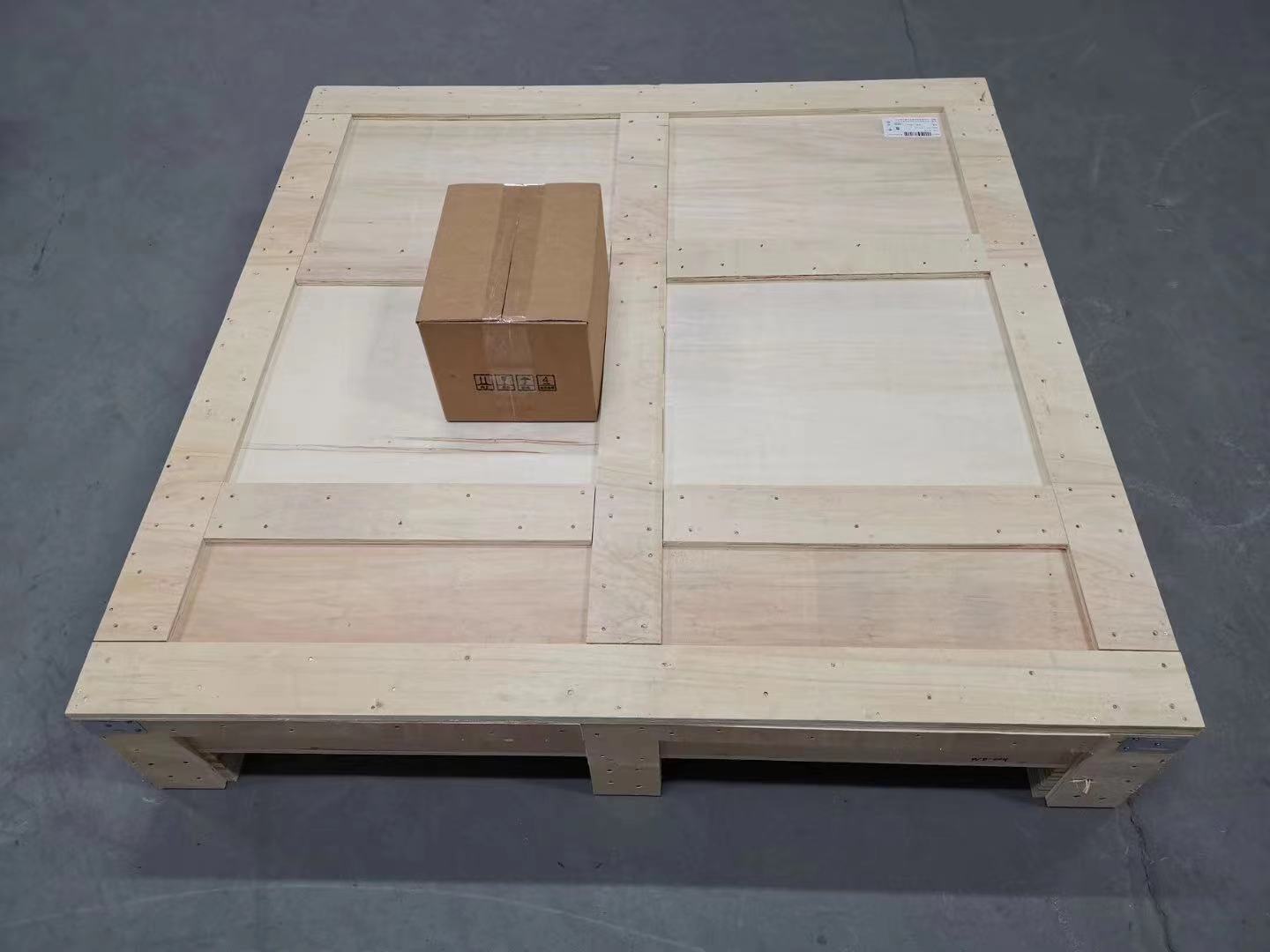

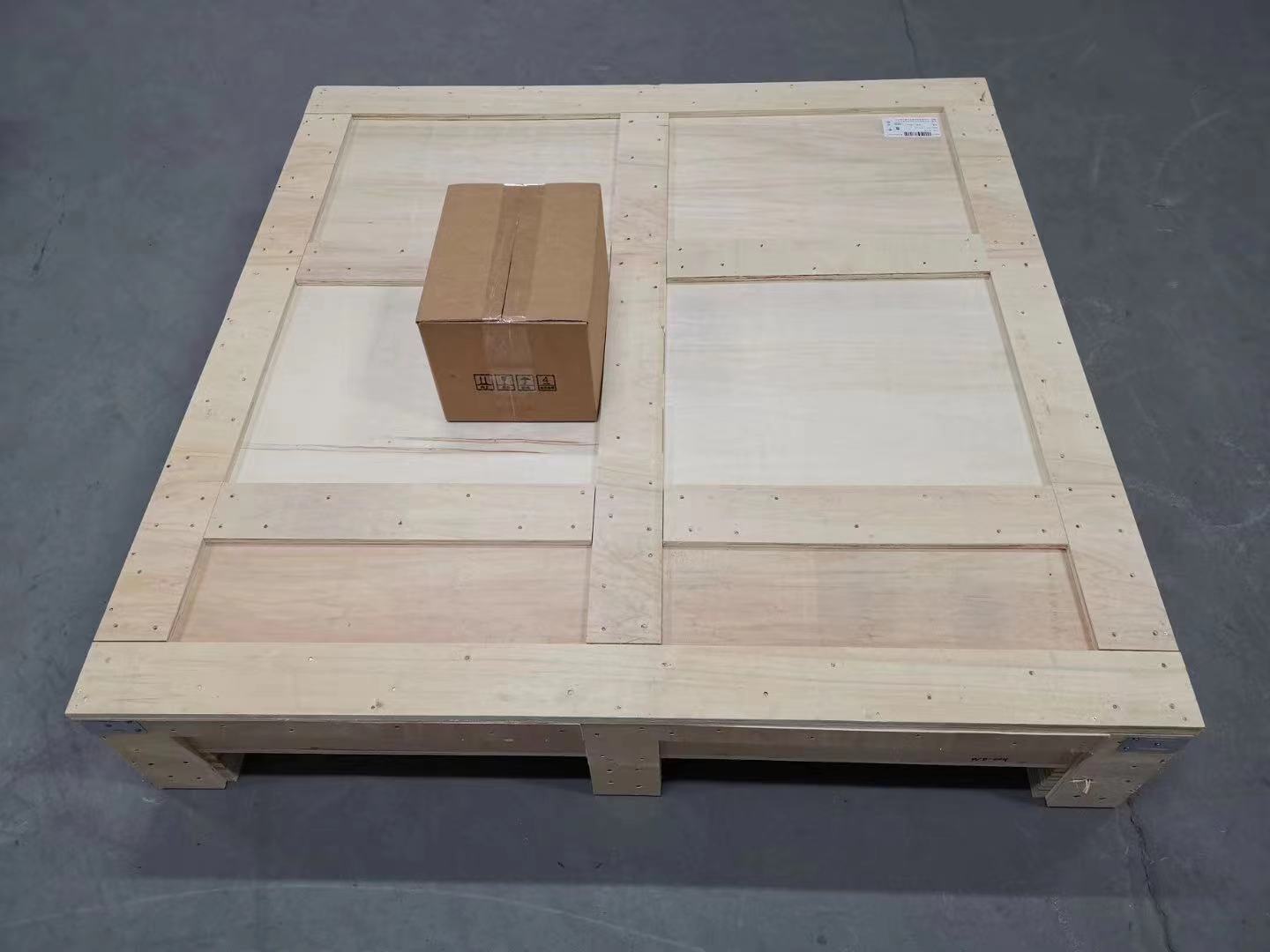

A carbon steel double deck floor scale is a heavy-duty weighing device designed to measure the weight of large and heavy objects. It consists of two layers (decks) of carbon steel, which provide enhanced stability and durability. These scales are commonly used in industrial and commercial settings where precision and reliability are paramount.

With high-precision sensors, clear digital displays, and multiple connectivity options, our floor scales integrate seamlessly into your operations, offering real-time data management and control. Safety features like overload protection and anti-slip surfaces ensure a secure working environment, giving you peace of mind while enhancing operational efficiency.

QC Weighing Floor Scale catalog.pdf

QC Weighing Floor Scale catalog.pdf

| Size | 800/1000/1200/1500mm/2000mm/3000mm/customized |

| Capacity | up to 10T |

| Lowest weighing height | 40mm |

| Material | Carbon steel |

| Power Supply | 220V(AC) |

| Display Type | LED/LCD |

| Regular Size | Capability | Division | Features |

| 0.8x0.8(m) | Up to 10T | 0.05KG~2KG | A) Double Deck B) Material: Carbon Steel (pattern design) C) U- Shape beams by moulds D) Working temperature: -10℃ ~ 60℃ E) Select Equipped with: ramp, large screen display, instrument bracket, ground scale frame, wireless configuration, USB storage and recording function,weight over-limit alarm function, self-adhesive label printer, receipt printer, dot matrix printer |

| 1.0x1.0(m) | |||

| 1.2x1.2(m) | |||

| 1.2x1.5(m) | |||

| 1.5x1.5(m) | |||

| 1.5x2.0(m) | |||

| 2.0x2.0(m) | |||

| 2.0x3.0(m) |

A carbon steel floor scale consists of several key components, each contributing to its functionality, durability, and precision. Here’s a breakdown of these components:

Material: Constructed from carbon steel for superior strength and corrosion resistance.

Function: These are the sensors that measure the weight of the objects placed on the platform.

Configuration: Usually, multiple load cells (typically four) are used to ensure even weight distribution and accurate measurements.

Display: Provides a clear digital readout of the weight measurement.

Functions: May include tare, zero, units conversion, and other functionalities

Purpose: Facilitate the loading and unloading of wheeled carts, pallets, and other heavy objects.

Material: Stainless steel construction to match the durability of the platform.

Function: Connects the load cells to the digital indicator.

Material: Often made of stainless steel or another durable material to protect against environmental factors.

Material: Typically carbon steel or heavy-duty rubber.

Purpose: Adjustable to ensure the scale is level and stable on uneven surfaces.

Low-profile floor scales are designed for ease of use, featuring a slim design that allows for easy loading and unloading of items. They are perfect for environments where space is limited and efficiency is crucial.

For businesses that require flexibility, portable floor scales are an excellent option. These scales are designed to be easily moved around, making them ideal for temporary setups or areas where the scale needs to be frequently relocated.

Installed in a pit so that the weighing platform is level with the floor, allowing for seamless loading and unloading.

Carbon steel is renowned for its robustness, making these floor scales exceptionally durable. They can withstand heavy loads and harsh working conditions without compromising their structural integrity.

Compared to other materials like stainless steel, carbon steel is more affordable while still offering high performance. This makes it a cost-effective solution for businesses needing reliable weighing equipment without breaking the bank.

Carbon steel floor scales are versatile and can be used in various industries, from warehouses and factories to farms and retail stores. Their ability to handle different types of loads makes them a versatile tool for any business.

The double deck design of these scales provides added stability. This design reduces the risk of tilting or uneven weight distribution, ensuring accurate measurements.

With two layers working together, the weight of the load is distributed more evenly. This helps in maintaining the integrity of the scale and prevents damage from overloading specific areas.

Double deck floor scales typically have a higher load capacity compared to their single deck counterparts. This makes them suitable for weighing extremely heavy items, common in industrial settings.

Always adhere to the maximum weight limit of your scale to prevent damage and ensure accurate measurements.

Regular maintenance is crucial. Neglecting cleaning and calibration can lead to inaccurate readings and reduced lifespan of the scale.

Without regular calibration, scales can become inaccurate over time. Make calibration a routine part of your maintenance schedule.

Used in warehouses, factories, and production lines for weighing raw materials, finished products, and machinery parts. Essential for quality control and inventory management.

Ideal for environments where hygiene is crucial, such as in the processing and packaging of food products. Easy to sanitize and resistant to rust and contaminants.

Used for precise measurement of ingredients and products in laboratories and production facilities. Stainless steel construction ensures compliance with sanitary and safety regulations.

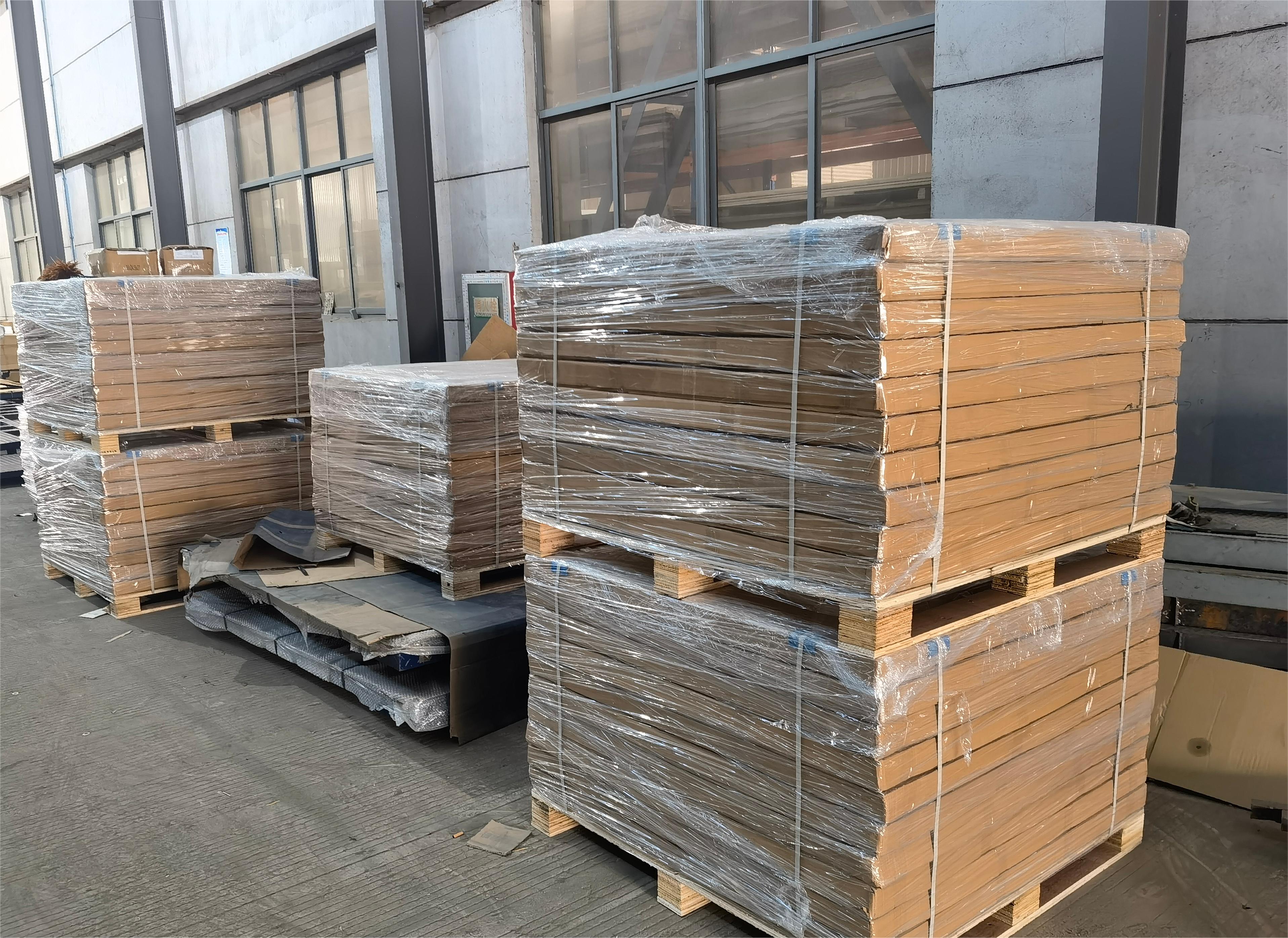

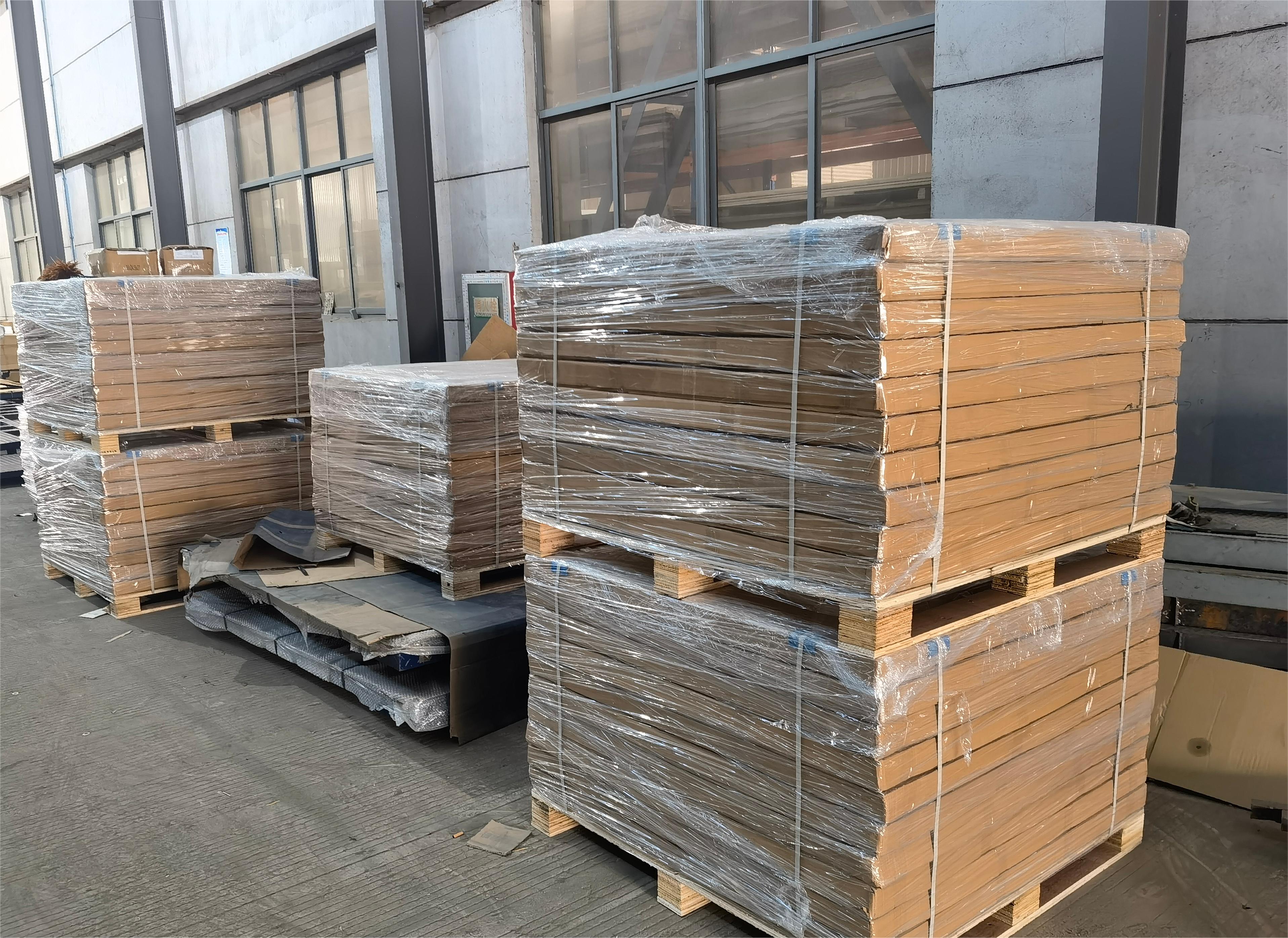

Facilitates accurate weighing of goods for shipping and receiving, ensuring compliance with transport regulations and optimizing shipping costs.

Double deck scales offer enhanced stability and weight distribution compared to single deck scales, making them suitable for heavier and more demanding applications.

While stainless steel offers superior corrosion resistance, carbon steel provides a more cost-effective solution with adequate durability and performance for many industrial applications.

Digital scales provide more accurate readings and are easier to read and integrate with other systems compared to analog scales. They are becoming the preferred choice in modern industries.

Provide ongoing training and support for operators responsible for using the truck scale. Ensure they understand proper operating procedures, safety protocols, and troubleshooting techniques to address common issues. Regular training sessions can improve efficiency and reduce the risk of operator errors.

Address any issues free and promptly in one year by repairing or replacing damaged or malfunctioning components. This may include replacing load cells, cables, junction boxes, or electronic parts that are no longer functioning properly(except for natural disasters and man-made damage).

Stay updated with the latest software releases and system upgrades for the truck scale. Install software updates provided by the manufacturer to enhance performance, add new features, or address security vulnerabilities. Consider upgrading the scale's system hardware if needed to meet changing operational requirements.

Maintain service agreements with qualified technicians or service providers 24h remote hotline technical assistance to urgent service requests and provide onsite assistance when needed.

A: Regular calibration is essential for maintaining accuracy. Depending on usage, calibrate your scale monthly or quarterly.

A: While carbon steel is durable, it may not be ideal for prolonged outdoor use without protection from the elements due to potential rusting.

A: With proper maintenance, a carbon steel floor scale can last many years. Regular cleaning and calibration significantly extend its lifespan.

A: Perform regular calibration and check against known weights. If the scale consistently shows accurate measurements, it is functioning correctly.

A: Erratic readings, no readings, or consistently inaccurate measurements can indicate a failing load cell. Regular inspection and testing can help identify these issues early.

Are you looking for a robust, accurate, and easy-to-use weighing solution for your industrial or commercial needs?

A carbon steel double deck floor scale is a heavy-duty weighing device designed to measure the weight of large and heavy objects. It consists of two layers (decks) of carbon steel, which provide enhanced stability and durability. These scales are commonly used in industrial and commercial settings where precision and reliability are paramount.

With high-precision sensors, clear digital displays, and multiple connectivity options, our floor scales integrate seamlessly into your operations, offering real-time data management and control. Safety features like overload protection and anti-slip surfaces ensure a secure working environment, giving you peace of mind while enhancing operational efficiency.

QC Weighing Floor Scale catalog.pdf

QC Weighing Floor Scale catalog.pdf

| Size | 800/1000/1200/1500mm/2000mm/3000mm/customized |

| Capacity | up to 10T |

| Lowest weighing height | 40mm |

| Material | Carbon steel |

| Power Supply | 220V(AC) |

| Display Type | LED/LCD |

| Regular Size | Capability | Division | Features |

| 0.8x0.8(m) | Up to 10T | 0.05KG~2KG | A) Double Deck B) Material: Carbon Steel (pattern design) C) U- Shape beams by moulds D) Working temperature: -10℃ ~ 60℃ E) Select Equipped with: ramp, large screen display, instrument bracket, ground scale frame, wireless configuration, USB storage and recording function,weight over-limit alarm function, self-adhesive label printer, receipt printer, dot matrix printer |

| 1.0x1.0(m) | |||

| 1.2x1.2(m) | |||

| 1.2x1.5(m) | |||

| 1.5x1.5(m) | |||

| 1.5x2.0(m) | |||

| 2.0x2.0(m) | |||

| 2.0x3.0(m) |

A carbon steel floor scale consists of several key components, each contributing to its functionality, durability, and precision. Here’s a breakdown of these components:

Material: Constructed from carbon steel for superior strength and corrosion resistance.

Function: These are the sensors that measure the weight of the objects placed on the platform.

Configuration: Usually, multiple load cells (typically four) are used to ensure even weight distribution and accurate measurements.

Display: Provides a clear digital readout of the weight measurement.

Functions: May include tare, zero, units conversion, and other functionalities

Purpose: Facilitate the loading and unloading of wheeled carts, pallets, and other heavy objects.

Material: Stainless steel construction to match the durability of the platform.

Function: Connects the load cells to the digital indicator.

Material: Often made of stainless steel or another durable material to protect against environmental factors.

Material: Typically carbon steel or heavy-duty rubber.

Purpose: Adjustable to ensure the scale is level and stable on uneven surfaces.

Low-profile floor scales are designed for ease of use, featuring a slim design that allows for easy loading and unloading of items. They are perfect for environments where space is limited and efficiency is crucial.

For businesses that require flexibility, portable floor scales are an excellent option. These scales are designed to be easily moved around, making them ideal for temporary setups or areas where the scale needs to be frequently relocated.

Installed in a pit so that the weighing platform is level with the floor, allowing for seamless loading and unloading.

Carbon steel is renowned for its robustness, making these floor scales exceptionally durable. They can withstand heavy loads and harsh working conditions without compromising their structural integrity.

Compared to other materials like stainless steel, carbon steel is more affordable while still offering high performance. This makes it a cost-effective solution for businesses needing reliable weighing equipment without breaking the bank.

Carbon steel floor scales are versatile and can be used in various industries, from warehouses and factories to farms and retail stores. Their ability to handle different types of loads makes them a versatile tool for any business.

The double deck design of these scales provides added stability. This design reduces the risk of tilting or uneven weight distribution, ensuring accurate measurements.

With two layers working together, the weight of the load is distributed more evenly. This helps in maintaining the integrity of the scale and prevents damage from overloading specific areas.

Double deck floor scales typically have a higher load capacity compared to their single deck counterparts. This makes them suitable for weighing extremely heavy items, common in industrial settings.

Always adhere to the maximum weight limit of your scale to prevent damage and ensure accurate measurements.

Regular maintenance is crucial. Neglecting cleaning and calibration can lead to inaccurate readings and reduced lifespan of the scale.

Without regular calibration, scales can become inaccurate over time. Make calibration a routine part of your maintenance schedule.

Used in warehouses, factories, and production lines for weighing raw materials, finished products, and machinery parts. Essential for quality control and inventory management.

Ideal for environments where hygiene is crucial, such as in the processing and packaging of food products. Easy to sanitize and resistant to rust and contaminants.

Used for precise measurement of ingredients and products in laboratories and production facilities. Stainless steel construction ensures compliance with sanitary and safety regulations.

Facilitates accurate weighing of goods for shipping and receiving, ensuring compliance with transport regulations and optimizing shipping costs.

Double deck scales offer enhanced stability and weight distribution compared to single deck scales, making them suitable for heavier and more demanding applications.

While stainless steel offers superior corrosion resistance, carbon steel provides a more cost-effective solution with adequate durability and performance for many industrial applications.

Digital scales provide more accurate readings and are easier to read and integrate with other systems compared to analog scales. They are becoming the preferred choice in modern industries.

Provide ongoing training and support for operators responsible for using the truck scale. Ensure they understand proper operating procedures, safety protocols, and troubleshooting techniques to address common issues. Regular training sessions can improve efficiency and reduce the risk of operator errors.

Address any issues free and promptly in one year by repairing or replacing damaged or malfunctioning components. This may include replacing load cells, cables, junction boxes, or electronic parts that are no longer functioning properly(except for natural disasters and man-made damage).

Stay updated with the latest software releases and system upgrades for the truck scale. Install software updates provided by the manufacturer to enhance performance, add new features, or address security vulnerabilities. Consider upgrading the scale's system hardware if needed to meet changing operational requirements.

Maintain service agreements with qualified technicians or service providers 24h remote hotline technical assistance to urgent service requests and provide onsite assistance when needed.

A: Regular calibration is essential for maintaining accuracy. Depending on usage, calibrate your scale monthly or quarterly.

A: While carbon steel is durable, it may not be ideal for prolonged outdoor use without protection from the elements due to potential rusting.

A: With proper maintenance, a carbon steel floor scale can last many years. Regular cleaning and calibration significantly extend its lifespan.

A: Perform regular calibration and check against known weights. If the scale consistently shows accurate measurements, it is functioning correctly.

A: Erratic readings, no readings, or consistently inaccurate measurements can indicate a failing load cell. Regular inspection and testing can help identify these issues early.