Explosion-proof Electronic Platform Scale

QC Weighing

Stainless Steel

0.8X0.8M~2X3M(or customized)

0.5T~10T

| Availability: | |

|---|---|

In the world of industrial weighing, safety and accuracy are paramount. That's where explosion-proof electronic platform scales come into play. But what exactly are these scales, and why are they so crucial in certain industries?

An explosion-proof electronic platform scale is a weighing device designed to operate safely in hazardous environments where flammable gases, vapors, or dust are present. These scales are built to prevent any sparks or heat that could ignite an explosive atmosphere, ensuring the safety of both personnel and property.

| Size | 800/1000/1200/1500mm/2000mm/3000mm/customized |

| Capacity | up to 10T |

| Material | Stainless steel |

| Power Supply | 220V(AC) |

| Display Type | LED/LCD |

| Features | High precision and stable performance |

| Regular Size | Capability | Division | Features |

| 0.8x0.8(m) | Up to 10T | 0.05KG~2KG | A) Explosion-proof B) Material: Stainless Steel C) U- Shape beams by moulds D) Working temperature: -10℃ ~ 60℃ E) Select Equipped with: ramp, large screen display, instrument bracket, ground scale frame, wireless configuration, USB storage and recording function,weight over-limit alarm function, self-adhesive label printer, receipt printer, dot matrix printer |

| 1.0x1.0(m) | |||

| 1.2x1.2(m) | |||

| 1.2x1.5(m) | |||

| 1.5x1.5(m) | |||

| 1.5x2.0(m) | |||

| 2.0x2.0(m) | |||

| 2.0x3.0(m) |

A stainless steel floor scale consists of several key components, each contributing to its functionality, durability, and precision. Here’s a breakdown of these components:

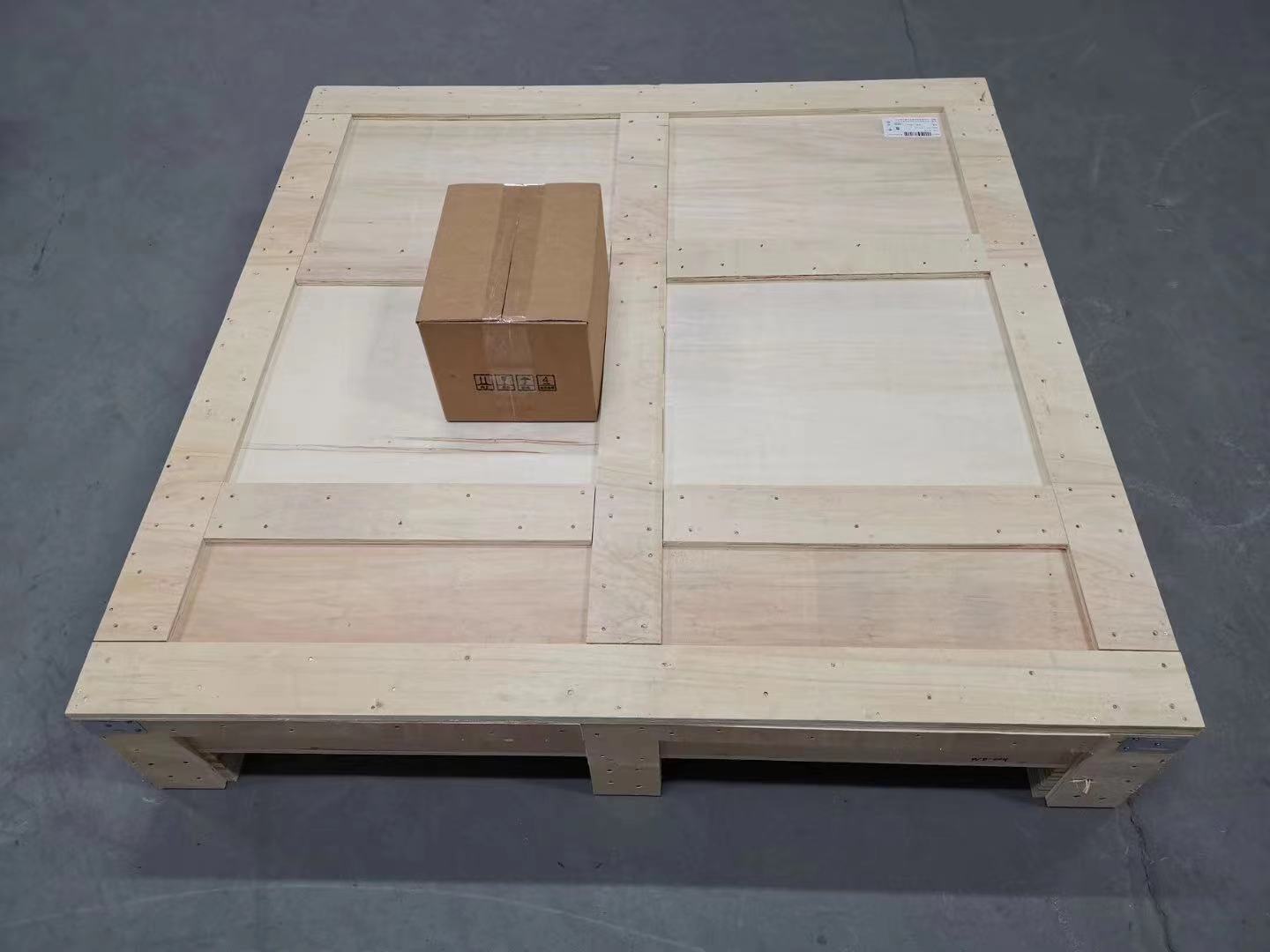

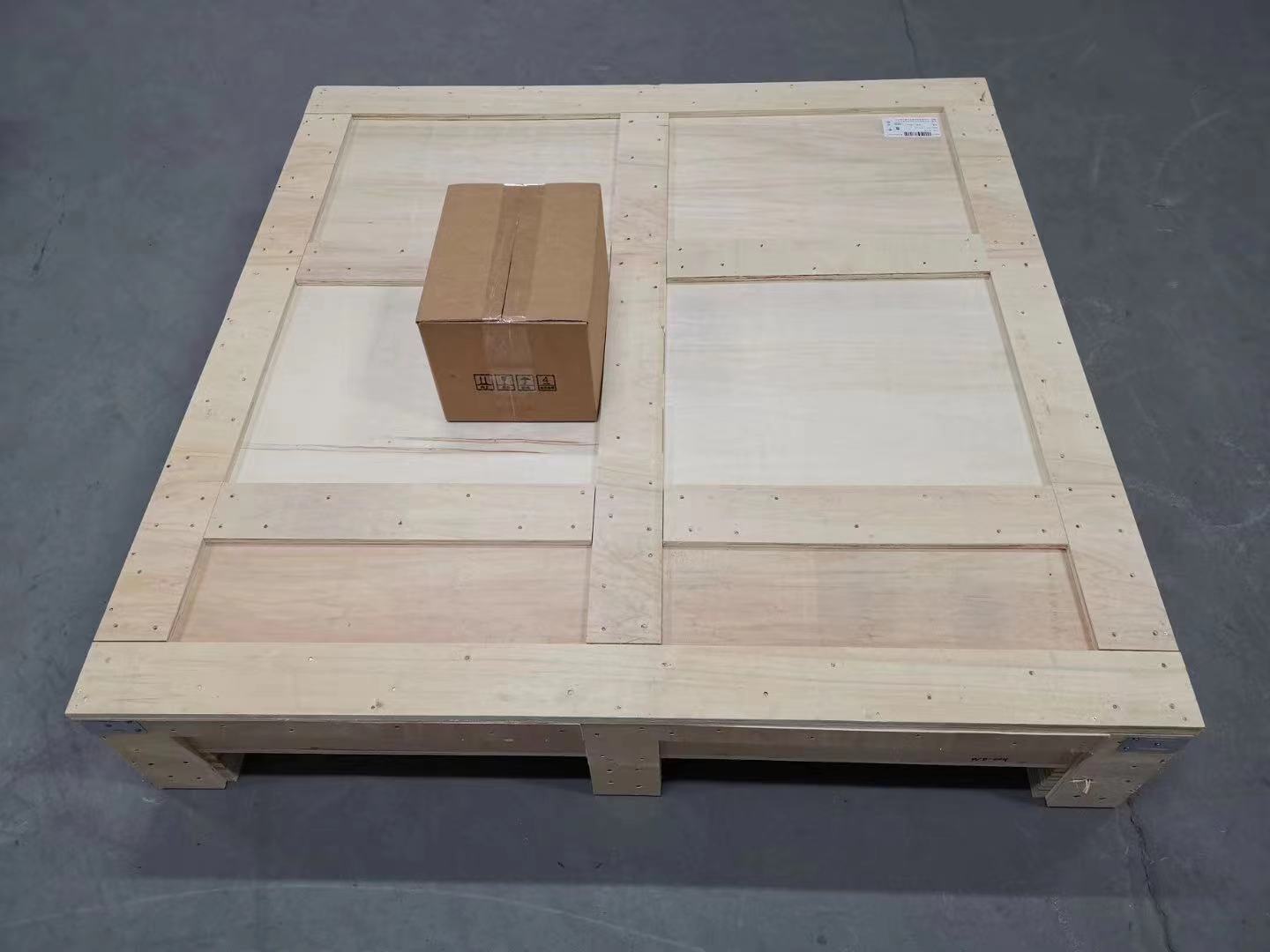

The platform is the weighing surface of the scale. In explosion-proof models, it is often made from durable, non-sparking materials like stainless steel.

Load cells are the sensors that measure the weight on the platform. In explosion-proof scales, these are designed to minimize the risk of sparking and are often enclosed in protective housings.

The indicator is the display unit that shows the weight readings. Explosion-proof indicators are sealed and protected to ensure they do not ignite the surrounding atmosphere.

Purpose: Facilitate the loading and unloading of wheeled carts, pallets, and other heavy objects.

Material: Stainless steel construction to match the durability of the platform.

Function: Connects the load cells to the digital indicator.

Material: Often made of stainless steel or another durable material to protect against environmental factors.

Material: Typically stainless steel or heavy-duty rubber.

Purpose: Adjustable to ensure the scale is level and stable on uneven surfaces.

Low-profile floor scales are designed for ease of use, featuring a slim design that allows for easy loading and unloading of items. They are perfect for environments where space is limited and efficiency is crucial.

For businesses that require flexibility, portable floor scales are an excellent option. These scales are designed to be easily moved around, making them ideal for temporary setups or areas where the scale needs to be frequently relocated.

Washdown floor scales are designed for environments where hygiene is paramount. Their stainless steel construction is resistant to moisture and chemicals, ensuring long-term durability and accurate performance in wet or sanitary conditions.

The primary benefit is the significant reduction in risk of explosions, protecting both workers and infrastructure.

Using explosion-proof equipment ensures compliance with industry safety standards and regulations, avoiding legal issues and potential fines.

Explosion-proof scales offer precise and reliable measurements, crucial for maintaining product quality and operational efficiency.

These scales are built to withstand harsh conditions, offering long-lasting performance and reliability.

Used in warehouses, factories, and production lines for weighing raw materials, finished products, and machinery parts. Essential for quality control and inventory management.

Ideal for environments where hygiene is crucial, such as in the processing and packaging of food products. Easy to sanitize and resistant to rust and contaminants.

Used for precise measurement of ingredients and products in laboratories and production facilities. Stainless steel construction ensures compliance with sanitary and safety regulations.

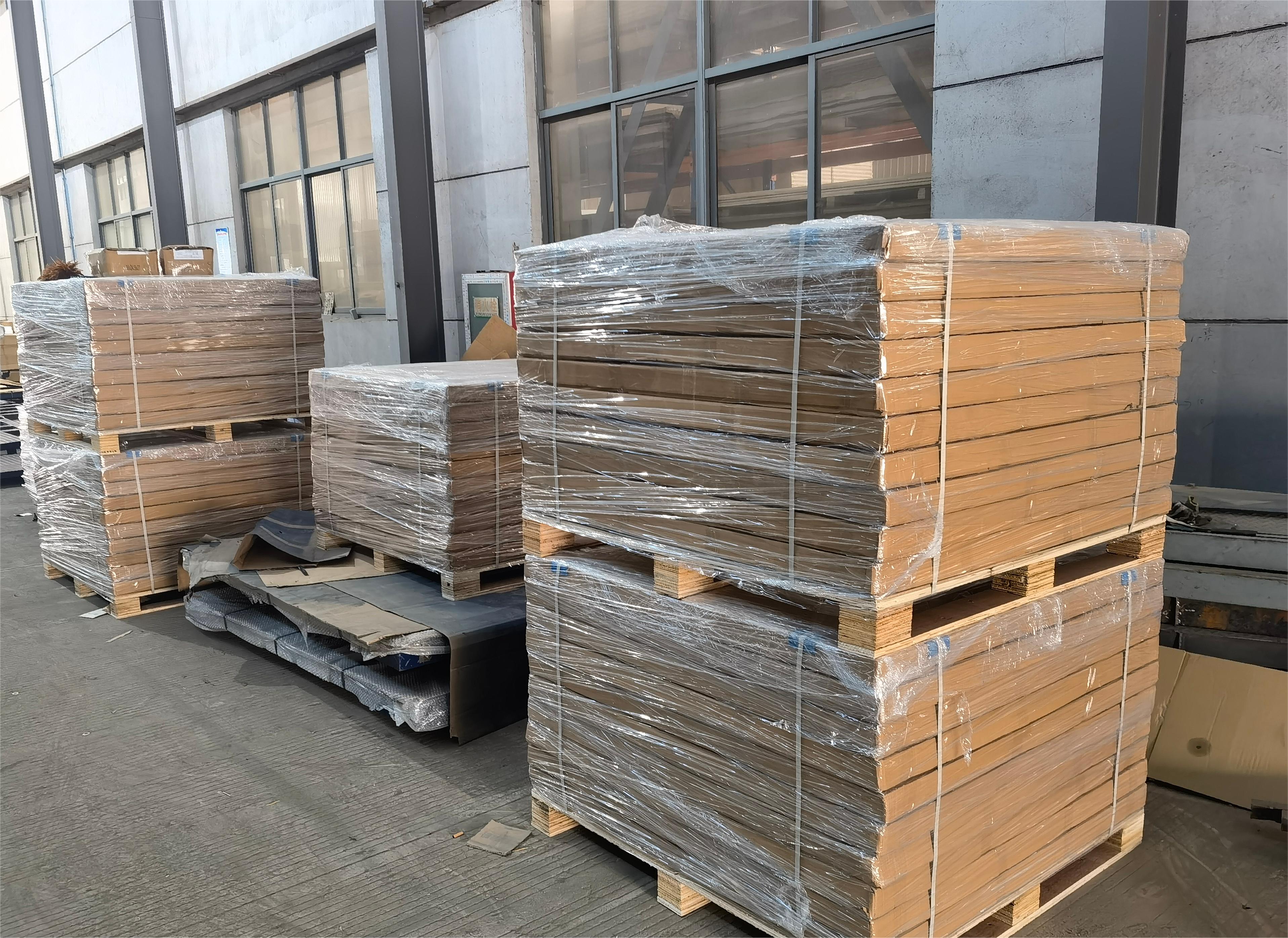

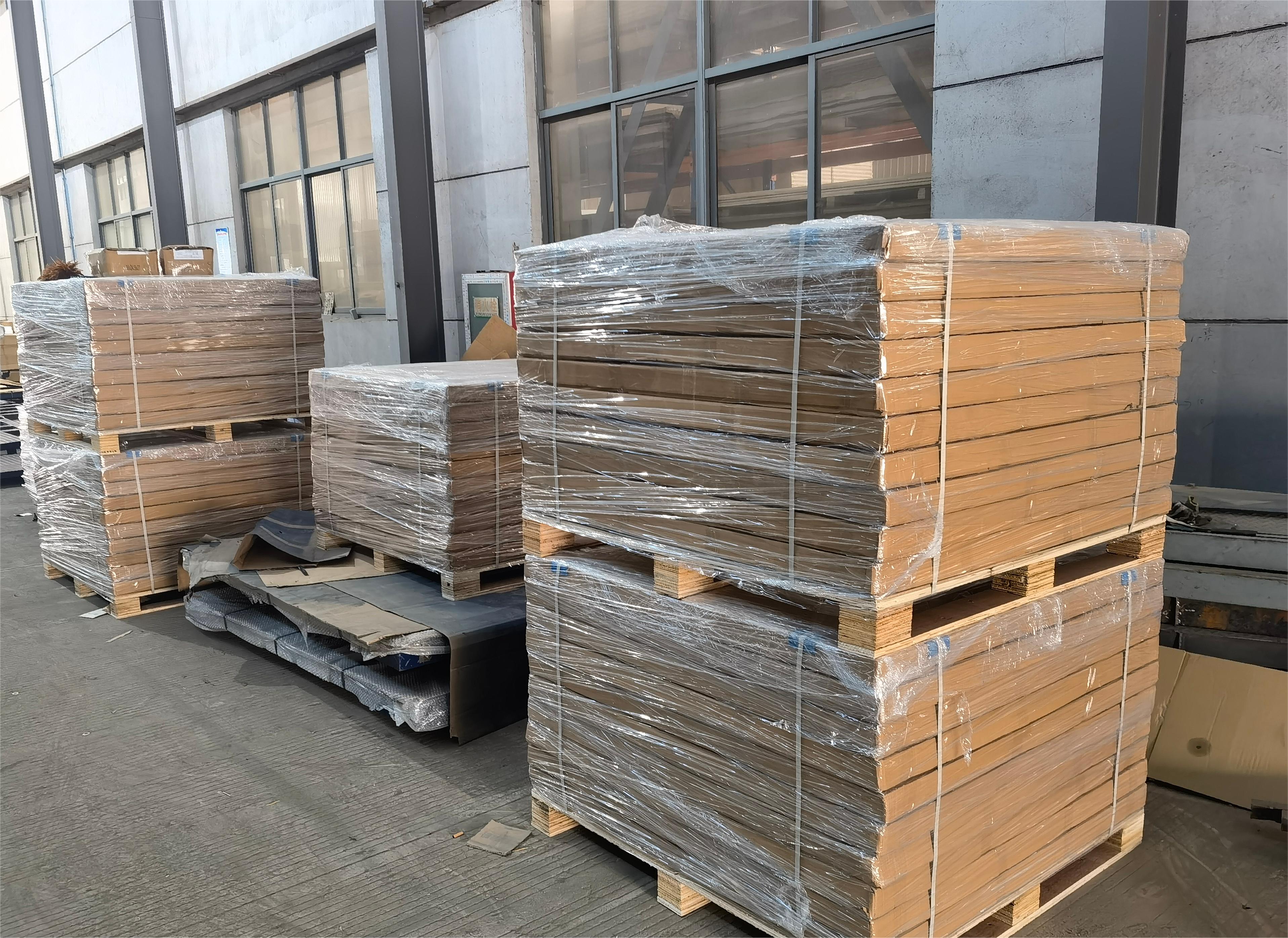

Facilitates accurate weighing of goods for shipping and receiving, ensuring compliance with transport regulations and optimizing shipping costs.

Provide ongoing training and support for operators responsible for using the truck scale. Ensure they understand proper operating procedures, safety protocols, and troubleshooting techniques to address common issues. Regular training sessions can improve efficiency and reduce the risk of operator errors.

Address any issues free and promptly in one year by repairing or replacing damaged or malfunctioning components. This may include replacing load cells, cables, junction boxes, or electronic parts that are no longer functioning properly(except for natural disasters and man-made damage).

Stay updated with the latest software releases and system upgrades for the truck scale. Install software updates provided by the manufacturer to enhance performance, add new features, or address security vulnerabilities. Consider upgrading the scale's system hardware if needed to meet changing operational requirements.

Maintain service agreements with qualified technicians or service providers 24h remote hotline technical assistance to urgent service requests and provide onsite assistance when needed.

A: According to the National Electrical Code (NEC), Ex Proof standard applies to an apparatus enclosed in a case that can withstand a gas or vapor explosion.

A: Yes, they are generally more expensive due to the specialized materials and construction required to ensure safety. However, the investment is justified by the enhanced safety and compliance with regulations.

A: Chemical processing, pharmaceuticals, oil and gas, among others.

In the world of industrial weighing, safety and accuracy are paramount. That's where explosion-proof electronic platform scales come into play. But what exactly are these scales, and why are they so crucial in certain industries?

An explosion-proof electronic platform scale is a weighing device designed to operate safely in hazardous environments where flammable gases, vapors, or dust are present. These scales are built to prevent any sparks or heat that could ignite an explosive atmosphere, ensuring the safety of both personnel and property.

| Size | 800/1000/1200/1500mm/2000mm/3000mm/customized |

| Capacity | up to 10T |

| Material | Stainless steel |

| Power Supply | 220V(AC) |

| Display Type | LED/LCD |

| Features | High precision and stable performance |

| Regular Size | Capability | Division | Features |

| 0.8x0.8(m) | Up to 10T | 0.05KG~2KG | A) Explosion-proof B) Material: Stainless Steel C) U- Shape beams by moulds D) Working temperature: -10℃ ~ 60℃ E) Select Equipped with: ramp, large screen display, instrument bracket, ground scale frame, wireless configuration, USB storage and recording function,weight over-limit alarm function, self-adhesive label printer, receipt printer, dot matrix printer |

| 1.0x1.0(m) | |||

| 1.2x1.2(m) | |||

| 1.2x1.5(m) | |||

| 1.5x1.5(m) | |||

| 1.5x2.0(m) | |||

| 2.0x2.0(m) | |||

| 2.0x3.0(m) |

A stainless steel floor scale consists of several key components, each contributing to its functionality, durability, and precision. Here’s a breakdown of these components:

The platform is the weighing surface of the scale. In explosion-proof models, it is often made from durable, non-sparking materials like stainless steel.

Load cells are the sensors that measure the weight on the platform. In explosion-proof scales, these are designed to minimize the risk of sparking and are often enclosed in protective housings.

The indicator is the display unit that shows the weight readings. Explosion-proof indicators are sealed and protected to ensure they do not ignite the surrounding atmosphere.

Purpose: Facilitate the loading and unloading of wheeled carts, pallets, and other heavy objects.

Material: Stainless steel construction to match the durability of the platform.

Function: Connects the load cells to the digital indicator.

Material: Often made of stainless steel or another durable material to protect against environmental factors.

Material: Typically stainless steel or heavy-duty rubber.

Purpose: Adjustable to ensure the scale is level and stable on uneven surfaces.

Low-profile floor scales are designed for ease of use, featuring a slim design that allows for easy loading and unloading of items. They are perfect for environments where space is limited and efficiency is crucial.

For businesses that require flexibility, portable floor scales are an excellent option. These scales are designed to be easily moved around, making them ideal for temporary setups or areas where the scale needs to be frequently relocated.

Washdown floor scales are designed for environments where hygiene is paramount. Their stainless steel construction is resistant to moisture and chemicals, ensuring long-term durability and accurate performance in wet or sanitary conditions.

The primary benefit is the significant reduction in risk of explosions, protecting both workers and infrastructure.

Using explosion-proof equipment ensures compliance with industry safety standards and regulations, avoiding legal issues and potential fines.

Explosion-proof scales offer precise and reliable measurements, crucial for maintaining product quality and operational efficiency.

These scales are built to withstand harsh conditions, offering long-lasting performance and reliability.

Used in warehouses, factories, and production lines for weighing raw materials, finished products, and machinery parts. Essential for quality control and inventory management.

Ideal for environments where hygiene is crucial, such as in the processing and packaging of food products. Easy to sanitize and resistant to rust and contaminants.

Used for precise measurement of ingredients and products in laboratories and production facilities. Stainless steel construction ensures compliance with sanitary and safety regulations.

Facilitates accurate weighing of goods for shipping and receiving, ensuring compliance with transport regulations and optimizing shipping costs.

Provide ongoing training and support for operators responsible for using the truck scale. Ensure they understand proper operating procedures, safety protocols, and troubleshooting techniques to address common issues. Regular training sessions can improve efficiency and reduce the risk of operator errors.

Address any issues free and promptly in one year by repairing or replacing damaged or malfunctioning components. This may include replacing load cells, cables, junction boxes, or electronic parts that are no longer functioning properly(except for natural disasters and man-made damage).

Stay updated with the latest software releases and system upgrades for the truck scale. Install software updates provided by the manufacturer to enhance performance, add new features, or address security vulnerabilities. Consider upgrading the scale's system hardware if needed to meet changing operational requirements.

Maintain service agreements with qualified technicians or service providers 24h remote hotline technical assistance to urgent service requests and provide onsite assistance when needed.

A: According to the National Electrical Code (NEC), Ex Proof standard applies to an apparatus enclosed in a case that can withstand a gas or vapor explosion.

A: Yes, they are generally more expensive due to the specialized materials and construction required to ensure safety. However, the investment is justified by the enhanced safety and compliance with regulations.

A: Chemical processing, pharmaceuticals, oil and gas, among others.