Buffering Scale

QC Weighing

Carbon Steel

1X1M~3X3M(or customized)

1T~50T

| Availability: | |

|---|---|

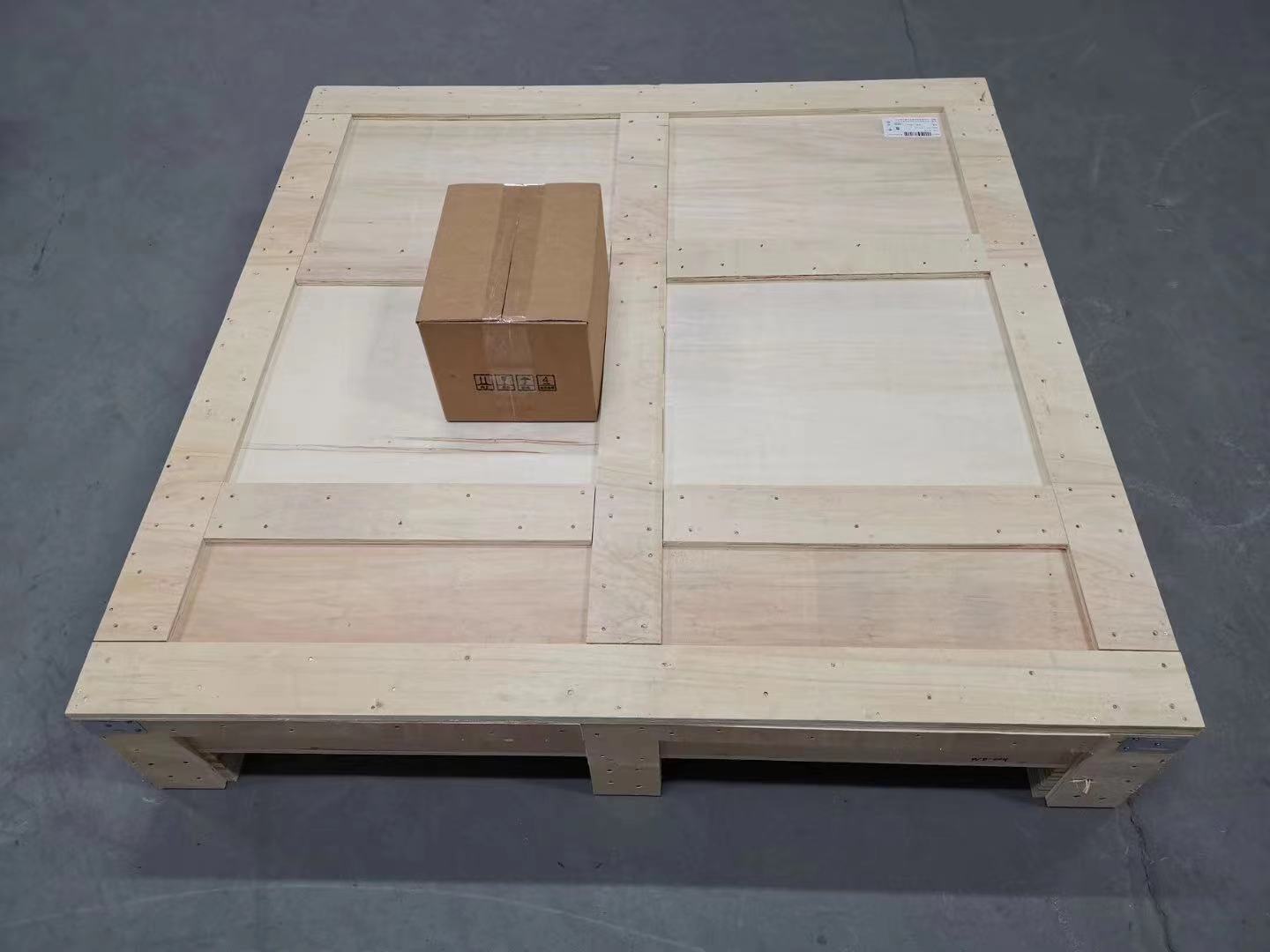

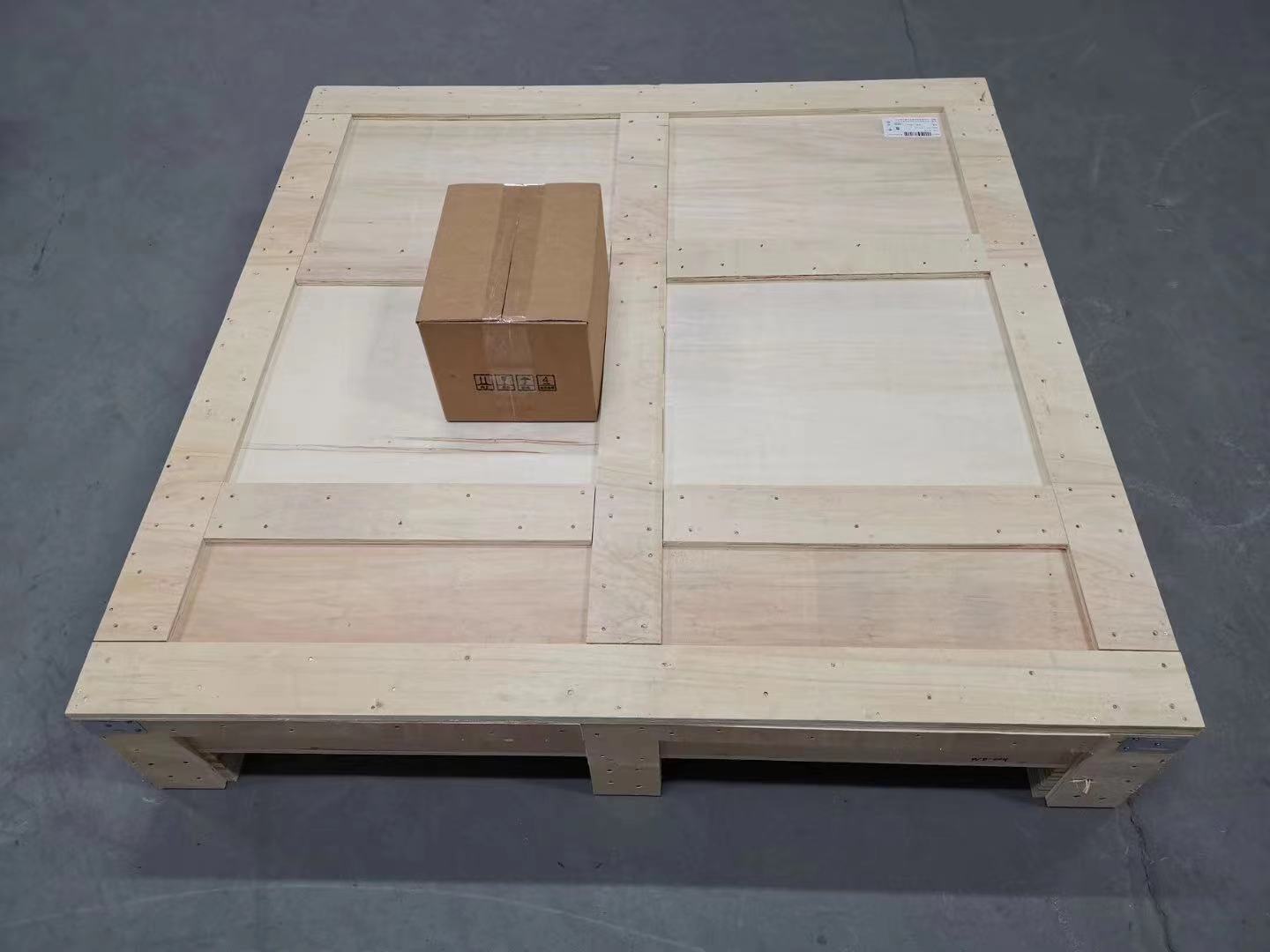

The three-layer buffer floor scale is designed with a three-layer scale body structure.

High-performance buffer shock absorbers are installed to absorb the impact energy during loading and avoid damage to the scale body during the measurement process.

Designed specifically for the measurement of high-density weighing items and working environments where the items have a strong impact on the scale body during the measurement process. For example: using lifting equipment to carry steel coils and paper rolls for measurement. The scale is resistant to stamping and fatigue, and has super performance.

| Size | 1000/1200/1500mm/2000mm/3000mm/customized |

| Capacity | up to 50T |

| Material | Carbon steel |

| Power Supply | 220V(AC) |

| Display Type | LED/LCD |

| Regular Size | Capability | Features |

| 1.0x1.0(m) | Up to 50T | A) Three-layer solid weighing platform B) Material: Carbon Steel (pattern design) C) Impact-resistant structure D) Equipped with four alloy steel weighing sensors E) Optional accuracy: 1/6000, special accuracy can be customized |

| 1.2x1.2(m) | ||

| 1.2x1.5(m) | ||

| 1.5x1.5(m) | ||

| 1.5x2.0(m) | ||

| 2.0x2.0(m) | ||

| 3.0x3.0(m) |

The entire scale is made of reinforced carbon steel. It is equipped with a high-precision shear beam weighing sensor.

A protective frame and protective bolts are added to the outside of the scale body to ensure that the scale body is not damaged or displaced by stamping during the measurement process.

The scale body can be connected to the optional weighing display for measurement.

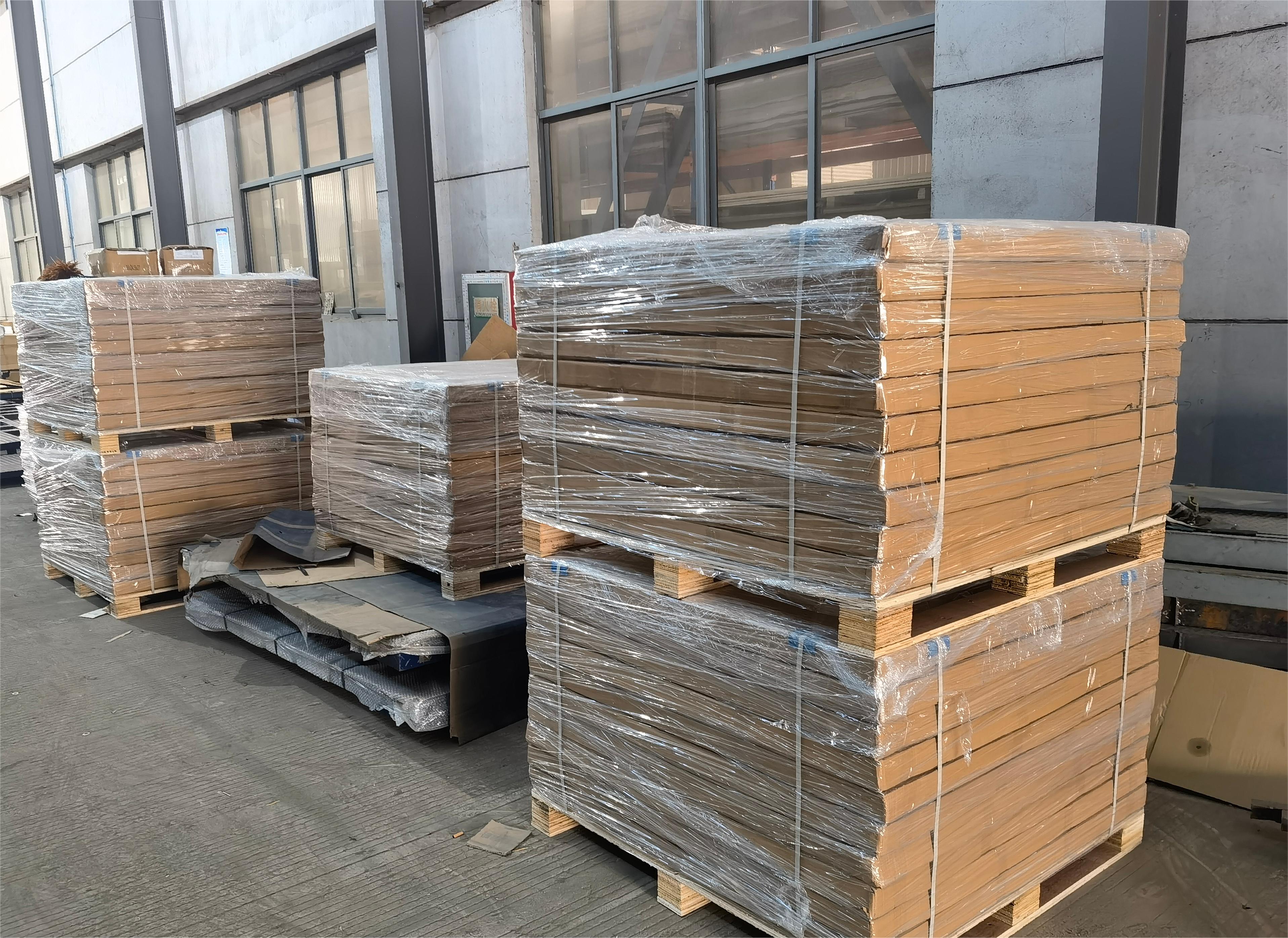

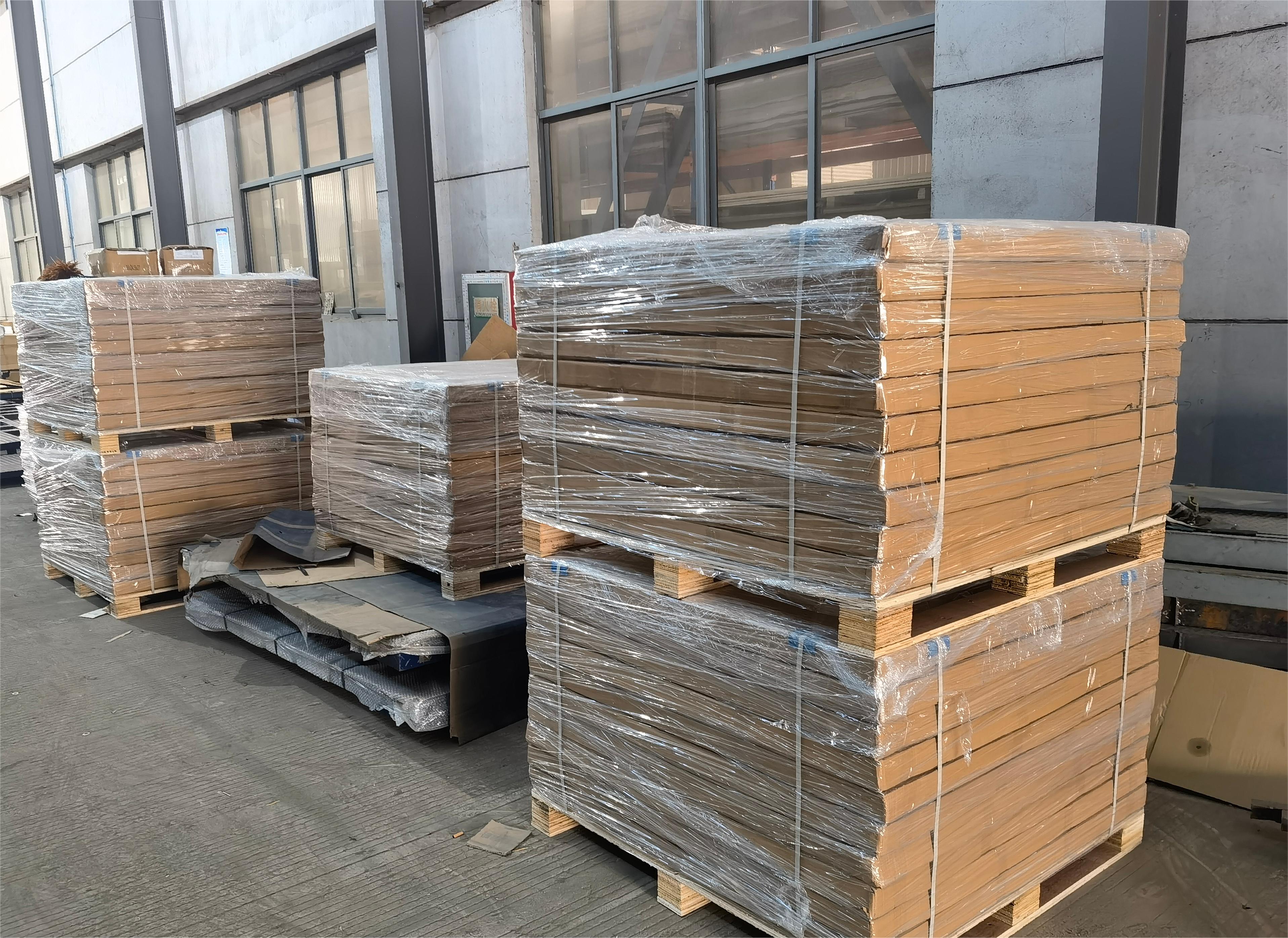

It is widely used in metallurgical casting, building materials, paper mills, warehousing and freight, inland docks, and heavy equipment manufacturing industries.

It is suitable for working environments where items have a strong impact on the scale body during the measurement process.

It is suitable for the measurement of high-density weighing items without causing damage to the body due to collapse.

The double deck design of these scales provides added stability. This design reduces the risk of tilting or uneven weight distribution, ensuring accurate measurements.

With two layers working together, the weight of the load is distributed more evenly. This helps in maintaining the integrity of the scale and prevents damage from overloading specific areas.

Double deck floor scales typically have a higher load capacity compared to their single deck counterparts. This makes them suitable for weighing extremely heavy items, common in industrial settings.

Always adhere to the maximum weight limit of your scale to prevent damage and ensure accurate measurements.

Regular maintenance is crucial. Neglecting cleaning and calibration can lead to inaccurate readings and reduced lifespan of the scale.

Without regular calibration, scales can become inaccurate over time. Make calibration a routine part of your maintenance schedule.

Used in warehouses, factories, and production lines for weighing raw materials, finished products, and machinery parts. Essential for quality control and inventory management.

Ideal for environments where hygiene is crucial, such as in the processing and packaging of food products. Easy to sanitize and resistant to rust and contaminants.

Used for precise measurement of ingredients and products in laboratories and production facilities. Stainless steel construction ensures compliance with sanitary and safety regulations.

Facilitates accurate weighing of goods for shipping and receiving, ensuring compliance with transport regulations and optimizing shipping costs.

Provide ongoing training and support for operators responsible for using the truck scale. Ensure they understand proper operating procedures, safety protocols, and troubleshooting techniques to address common issues. Regular training sessions can improve efficiency and reduce the risk of operator errors.

Address any issues free and promptly in one year by repairing or replacing damaged or malfunctioning components. This may include replacing load cells, cables, junction boxes, or electronic parts that are no longer functioning properly(except for natural disasters and man-made damage).

Stay updated with the latest software releases and system upgrades for the truck scale. Install software updates provided by the manufacturer to enhance performance, add new features, or address security vulnerabilities. Consider upgrading the scale's system hardware if needed to meet changing operational requirements.

Maintain service agreements with qualified technicians or service providers 24h remote hotline technical assistance to urgent service requests and provide onsite assistance when needed.

A: Regular calibration is essential for maintaining accuracy. Depending on usage, calibrate your scale monthly or quarterly.

A: Perform regular calibration and check against known weights. If the scale consistently shows accurate measurements, it is functioning correctly.

A: Erratic readings, no readings, or consistently inaccurate measurements can indicate a failing load cell. Regular inspection and testing can help identify these issues early.

The three-layer buffer floor scale is designed with a three-layer scale body structure.

High-performance buffer shock absorbers are installed to absorb the impact energy during loading and avoid damage to the scale body during the measurement process.

Designed specifically for the measurement of high-density weighing items and working environments where the items have a strong impact on the scale body during the measurement process. For example: using lifting equipment to carry steel coils and paper rolls for measurement. The scale is resistant to stamping and fatigue, and has super performance.

| Size | 1000/1200/1500mm/2000mm/3000mm/customized |

| Capacity | up to 50T |

| Material | Carbon steel |

| Power Supply | 220V(AC) |

| Display Type | LED/LCD |

| Regular Size | Capability | Features |

| 1.0x1.0(m) | Up to 50T | A) Three-layer solid weighing platform B) Material: Carbon Steel (pattern design) C) Impact-resistant structure D) Equipped with four alloy steel weighing sensors E) Optional accuracy: 1/6000, special accuracy can be customized |

| 1.2x1.2(m) | ||

| 1.2x1.5(m) | ||

| 1.5x1.5(m) | ||

| 1.5x2.0(m) | ||

| 2.0x2.0(m) | ||

| 3.0x3.0(m) |

The entire scale is made of reinforced carbon steel. It is equipped with a high-precision shear beam weighing sensor.

A protective frame and protective bolts are added to the outside of the scale body to ensure that the scale body is not damaged or displaced by stamping during the measurement process.

The scale body can be connected to the optional weighing display for measurement.

It is widely used in metallurgical casting, building materials, paper mills, warehousing and freight, inland docks, and heavy equipment manufacturing industries.

It is suitable for working environments where items have a strong impact on the scale body during the measurement process.

It is suitable for the measurement of high-density weighing items without causing damage to the body due to collapse.

The double deck design of these scales provides added stability. This design reduces the risk of tilting or uneven weight distribution, ensuring accurate measurements.

With two layers working together, the weight of the load is distributed more evenly. This helps in maintaining the integrity of the scale and prevents damage from overloading specific areas.

Double deck floor scales typically have a higher load capacity compared to their single deck counterparts. This makes them suitable for weighing extremely heavy items, common in industrial settings.

Always adhere to the maximum weight limit of your scale to prevent damage and ensure accurate measurements.

Regular maintenance is crucial. Neglecting cleaning and calibration can lead to inaccurate readings and reduced lifespan of the scale.

Without regular calibration, scales can become inaccurate over time. Make calibration a routine part of your maintenance schedule.

Used in warehouses, factories, and production lines for weighing raw materials, finished products, and machinery parts. Essential for quality control and inventory management.

Ideal for environments where hygiene is crucial, such as in the processing and packaging of food products. Easy to sanitize and resistant to rust and contaminants.

Used for precise measurement of ingredients and products in laboratories and production facilities. Stainless steel construction ensures compliance with sanitary and safety regulations.

Facilitates accurate weighing of goods for shipping and receiving, ensuring compliance with transport regulations and optimizing shipping costs.

Provide ongoing training and support for operators responsible for using the truck scale. Ensure they understand proper operating procedures, safety protocols, and troubleshooting techniques to address common issues. Regular training sessions can improve efficiency and reduce the risk of operator errors.

Address any issues free and promptly in one year by repairing or replacing damaged or malfunctioning components. This may include replacing load cells, cables, junction boxes, or electronic parts that are no longer functioning properly(except for natural disasters and man-made damage).

Stay updated with the latest software releases and system upgrades for the truck scale. Install software updates provided by the manufacturer to enhance performance, add new features, or address security vulnerabilities. Consider upgrading the scale's system hardware if needed to meet changing operational requirements.

Maintain service agreements with qualified technicians or service providers 24h remote hotline technical assistance to urgent service requests and provide onsite assistance when needed.

A: Regular calibration is essential for maintaining accuracy. Depending on usage, calibrate your scale monthly or quarterly.

A: Perform regular calibration and check against known weights. If the scale consistently shows accurate measurements, it is functioning correctly.

A: Erratic readings, no readings, or consistently inaccurate measurements can indicate a failing load cell. Regular inspection and testing can help identify these issues early.