Low Profile Floor Scale with Ramps

QC Weighing

Stainless Steel

0.8X0.8M~1.5X1.5M(or customized)

0.5T~2.5T

| Availability: | |

|---|---|

In industries ranging from manufacturing to logistics, accurate weight measurement is critical for ensuring operational efficiency and compliance with regulations. One versatile tool for achieving precise measurements is the low profile floor scale made of carbon steel. This article delves into the specifics of these scales and why they are a valuable asset in various settings.

A low profile floor scale is a weighing device designed with a minimal height from the ground, making it easier to load and unload items. It consists of a durable platform, precision sensors, and a digital or analog indicator for displaying weight measurements. These scales are commonly used in environments where space and efficiency are paramount.

QC WEIGHING low profile floor scale.pdf

QC WEIGHING low profile floor scale.pdf

| Size | 800/1000/1200/1500mm |

| Capacity | up to 2.5T |

| Material | Stainless steel |

| Power Supply | 220V(AC) |

| Display Type | LED/LCD |

| Regular Size | Capability | Division | Features |

| 0.8x0.8(m) | Up to 2.5T | 0.05KG~0.5KG | A) Low Profile B) Material: Stainless steel C) U- Shape beams by moulds D) Working temperature: -10℃ ~ 60℃ E) Select Equipped with: ramp, large screen display, instrument bracket, ground scale frame, wireless configuration, USB storage and recording function,weight over-limit alarm function, self-adhesive label printer, receipt printer, dot matrix printer |

| 1.0x1.0(m) | |||

| 1.2x1.2(m) | |||

| 1.2x1.5(m) | |||

| 1.5x1.5(m) |

The whole has a frame and a low table, with self-limiting and fixed scale position.

The tumbler sensor and automatic reset function ensure that the scale is not damaged and the measurement is accurate.

Suitable for human vehicle weighing, saving effort and time.

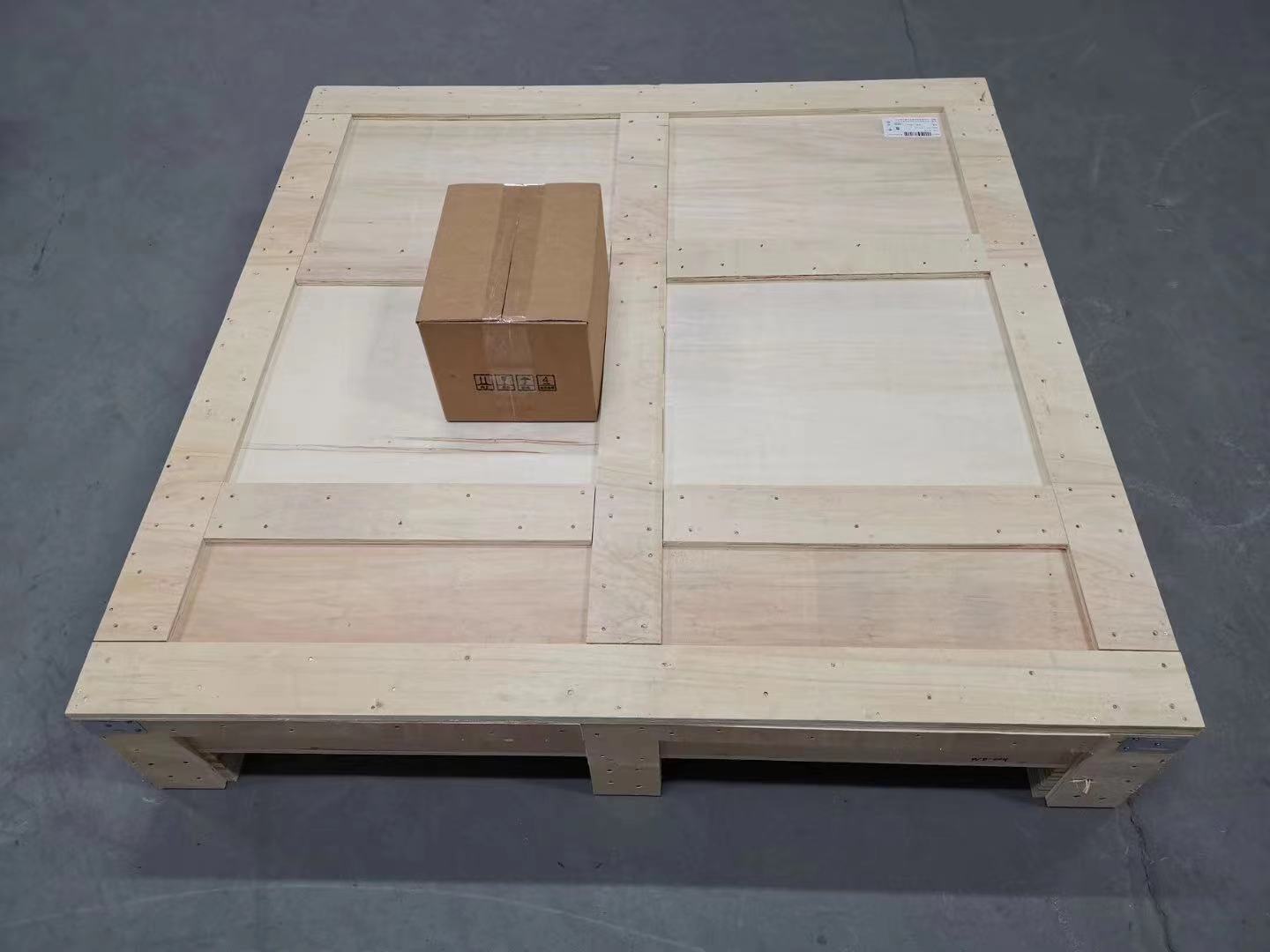

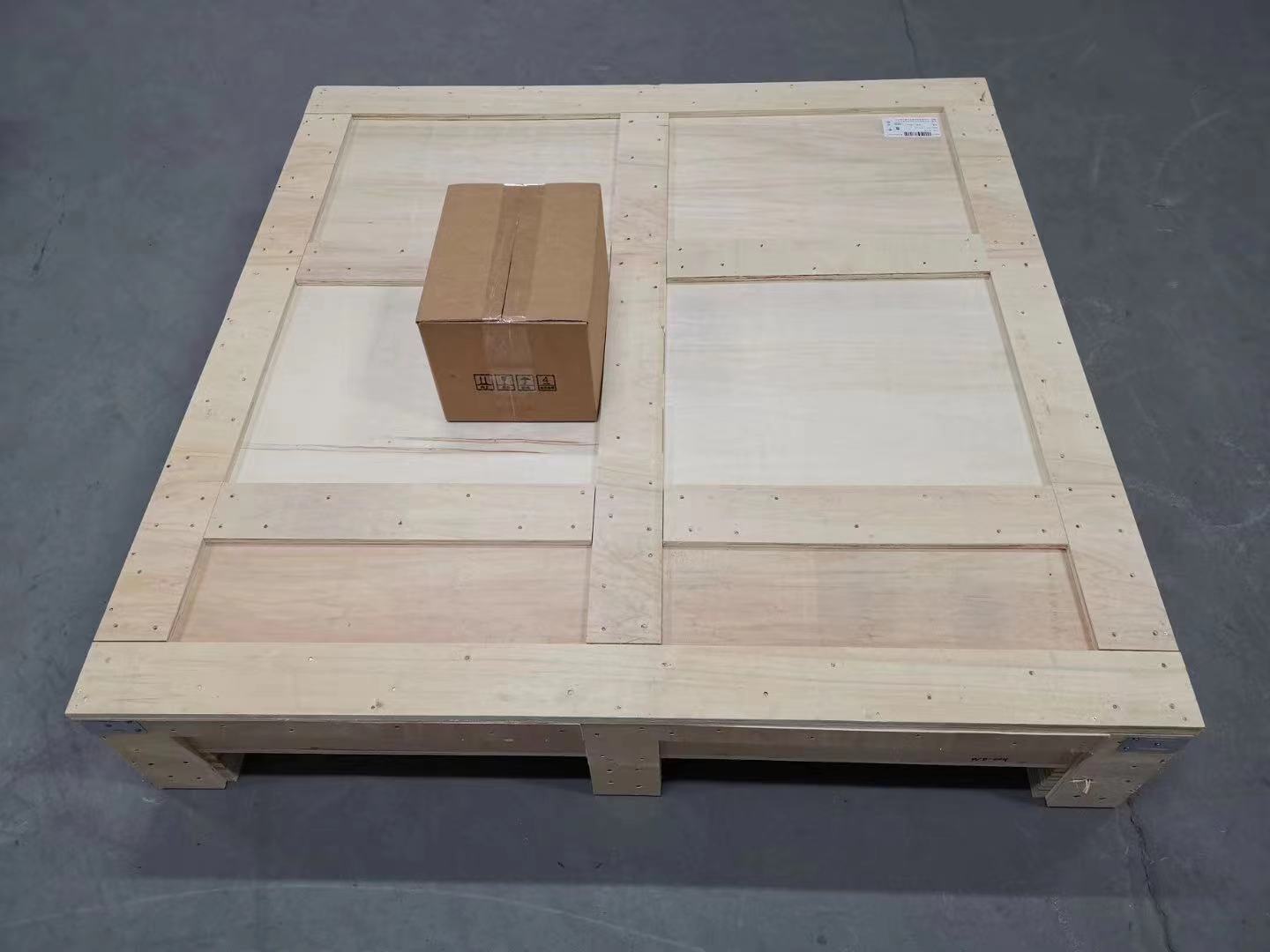

Standard double-slope guide structure, which can be folded when moving, saving transportation space, easy to disassemble and transport, and the scale body is easy to move.

A low profile floor scale stainless steel consists of several key components, each contributing to its functionality, durability, and precision. Here’s a breakdown of these components:

Material: Constructed from carbon steel for superior strength and corrosion resistance.

Function: These are the sensors that measure the weight of the objects placed on the platform.

Configuration: Usually, multiple load cells (typically four) are used to ensure even weight distribution and accurate measurements.

Display: Provides a clear digital readout of the weight measurement.

Functions: May include tare, zero, units conversion, and other functionalities.

Purpose: Facilitate the loading and unloading of wheeled carts, pallets, and other heavy objects.

Material: Stainless steel construction to match the durability of the platform.

Function: Connects the load cells to the digital indicator.

Material: Often made of stainless steel or another durable material to protect against environmental factors.

Material: Typically carbon steel or heavy-duty rubber.

Purpose: Adjustable to ensure the scale is level and stable on uneven surfaces.

The low height of these scales simplifies the process of loading and unloading items, reducing the need for ramps or lifting equipment.

Low profile scales take up less vertical space, making them ideal for areas with limited headroom or where maximizing space efficiency is crucial.

With a lower height, the risk of accidents related to lifting and dropping heavy items is minimized, promoting a safer working environment.

These scales are equipped with high precision sensors that provide accurate weight measurements, essential for maintaining quality control and operational efficiency.

Modern low profile floor scales often feature digital indicators that are easy to read and operate. These indicators may include backlit displays for visibility in low-light conditions and additional functions like tare weight and unit conversion.

The platform of a carbon steel floor scale is designed to withstand heavy use and is resistant to wear and tear, ensuring long-term reliability.

Low profile scales offer easier access and space-saving benefits compared to high profile scales, which may be necessary for certain heavy-duty applications.

While stainless steel offers superior corrosion resistance, carbon steel provides strength and durability at a lower cost, making it suitable for many industrial applications.

Digital scales, with their precise readings and user-friendly interfaces, are generally preferred over analog scales, which may be less accurate and harder to read.

Used in warehouses, factories, and production lines for weighing raw materials, finished products, and machinery parts. Essential for quality control and inventory management.

Ideal for environments where hygiene is crucial, such as in the processing and packaging of food products. Easy to sanitize and resistant to rust and contaminants.

Used for precise measurement of ingredients and products in laboratories and production facilities. Stainless steel construction ensures compliance with sanitary and safety regulations.

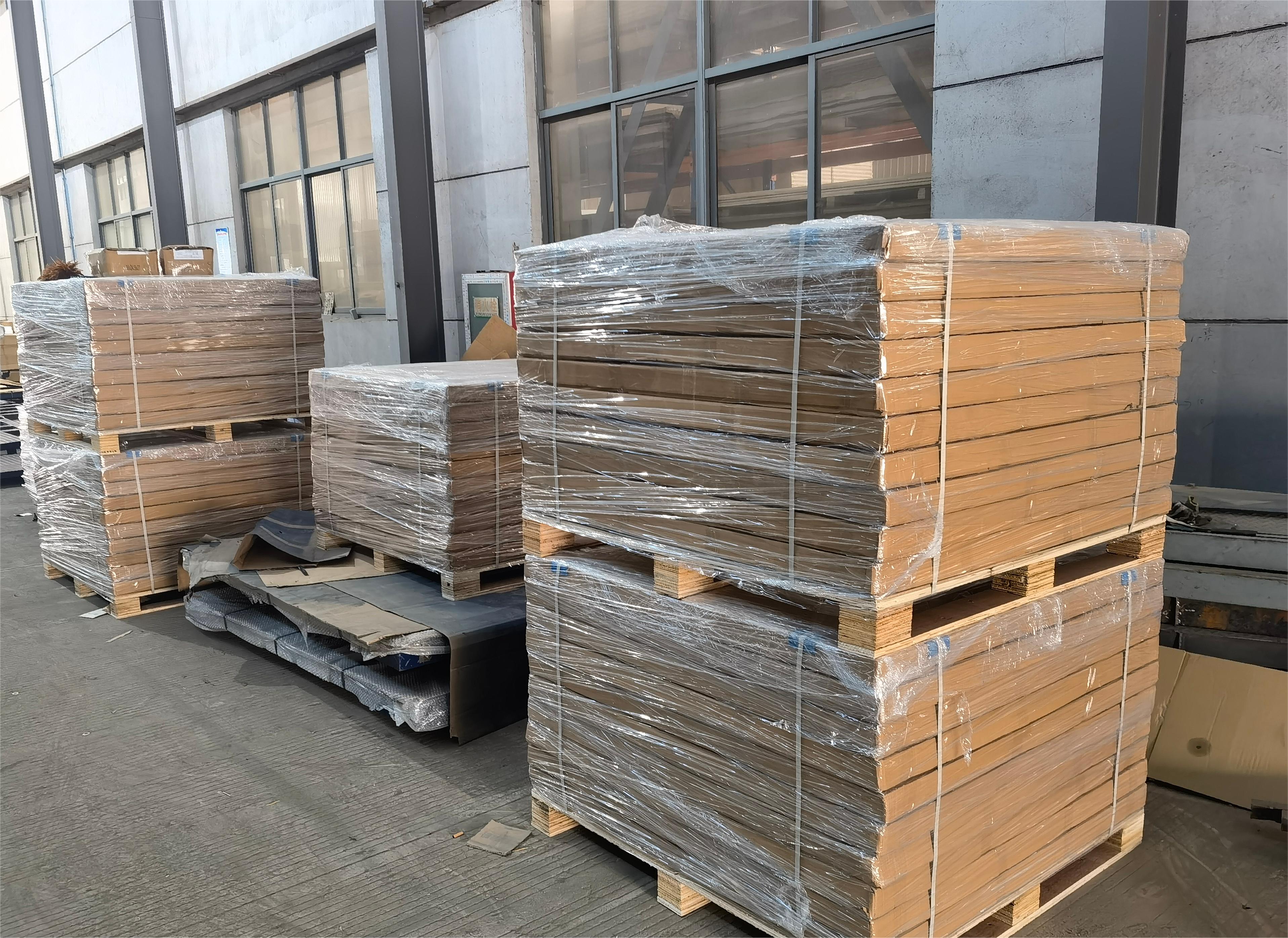

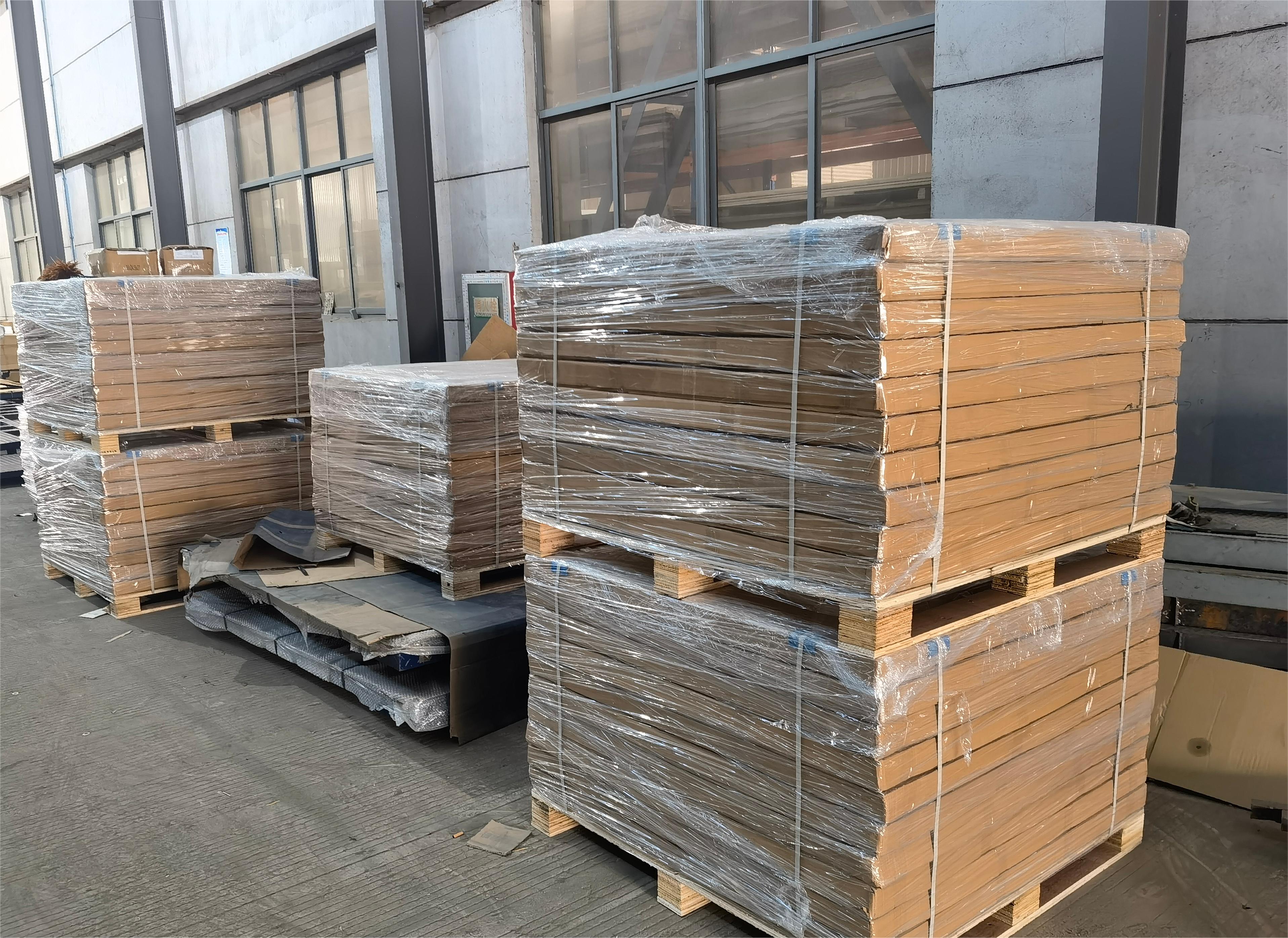

Facilitates accurate weighing of goods for shipping and receiving, ensuring compliance with transport regulations and optimizing shipping costs.

Provide ongoing training and support for operators responsible for using the truck scale. Ensure they understand proper operating procedures, safety protocols, and troubleshooting techniques to address common issues. Regular training sessions can improve efficiency and reduce the risk of operator errors.

Address any issues free and promptly in one year by repairing or replacing damaged or malfunctioning components. This may include replacing load cells, cables, junction boxes, or electronic parts that are no longer functioning properly(except for natural disasters and man-made damage).

Stay updated with the latest software releases and system upgrades for the truck scale. Install software updates provided by the manufacturer to enhance performance, add new features, or address security vulnerabilities. Consider upgrading the scale's system hardware if needed to meet changing operational requirements.

Maintain service agreements with qualified technicians or service providers 24h remote hotline technical assistance to urgent service requests and provide onsite assistance when needed.

A: Common materials include stainless steel and mild steel, which offer durability and resistance to corrosion. Stainless steel models are preferred in food processing and pharmaceutical industries.

A: Weight capacity can vary widely depending on the model, typically ranging from 1,000 to 20,000 pounds. Check your scale’s specifications for its exact capacity.

A: A low profile design makes it easier to load and unload items, reducing the need for additional equipment like ramps or lifts. This design is space-efficient and improves safety.

A: Ramps are not always necessary but can be very useful in certain situations, such as when using forklifts or pallet jacks to load heavy items onto the scale. They help improve ease of use and safety by providing a smooth transition onto the weighing platform. Ramps can be removable or permanently attached, depending on your needs.

A: Reset procedures vary by model. Generally, you may need to power cycle the scale or use a reset function provided in the user interface. Refer to the user manual for specific instructions.

In industries ranging from manufacturing to logistics, accurate weight measurement is critical for ensuring operational efficiency and compliance with regulations. One versatile tool for achieving precise measurements is the low profile floor scale made of carbon steel. This article delves into the specifics of these scales and why they are a valuable asset in various settings.

A low profile floor scale is a weighing device designed with a minimal height from the ground, making it easier to load and unload items. It consists of a durable platform, precision sensors, and a digital or analog indicator for displaying weight measurements. These scales are commonly used in environments where space and efficiency are paramount.

QC WEIGHING low profile floor scale.pdf

QC WEIGHING low profile floor scale.pdf

| Size | 800/1000/1200/1500mm |

| Capacity | up to 2.5T |

| Material | Stainless steel |

| Power Supply | 220V(AC) |

| Display Type | LED/LCD |

| Regular Size | Capability | Division | Features |

| 0.8x0.8(m) | Up to 2.5T | 0.05KG~0.5KG | A) Low Profile B) Material: Stainless steel C) U- Shape beams by moulds D) Working temperature: -10℃ ~ 60℃ E) Select Equipped with: ramp, large screen display, instrument bracket, ground scale frame, wireless configuration, USB storage and recording function,weight over-limit alarm function, self-adhesive label printer, receipt printer, dot matrix printer |

| 1.0x1.0(m) | |||

| 1.2x1.2(m) | |||

| 1.2x1.5(m) | |||

| 1.5x1.5(m) |

The whole has a frame and a low table, with self-limiting and fixed scale position.

The tumbler sensor and automatic reset function ensure that the scale is not damaged and the measurement is accurate.

Suitable for human vehicle weighing, saving effort and time.

Standard double-slope guide structure, which can be folded when moving, saving transportation space, easy to disassemble and transport, and the scale body is easy to move.

A low profile floor scale stainless steel consists of several key components, each contributing to its functionality, durability, and precision. Here’s a breakdown of these components:

Material: Constructed from carbon steel for superior strength and corrosion resistance.

Function: These are the sensors that measure the weight of the objects placed on the platform.

Configuration: Usually, multiple load cells (typically four) are used to ensure even weight distribution and accurate measurements.

Display: Provides a clear digital readout of the weight measurement.

Functions: May include tare, zero, units conversion, and other functionalities.

Purpose: Facilitate the loading and unloading of wheeled carts, pallets, and other heavy objects.

Material: Stainless steel construction to match the durability of the platform.

Function: Connects the load cells to the digital indicator.

Material: Often made of stainless steel or another durable material to protect against environmental factors.

Material: Typically carbon steel or heavy-duty rubber.

Purpose: Adjustable to ensure the scale is level and stable on uneven surfaces.

The low height of these scales simplifies the process of loading and unloading items, reducing the need for ramps or lifting equipment.

Low profile scales take up less vertical space, making them ideal for areas with limited headroom or where maximizing space efficiency is crucial.

With a lower height, the risk of accidents related to lifting and dropping heavy items is minimized, promoting a safer working environment.

These scales are equipped with high precision sensors that provide accurate weight measurements, essential for maintaining quality control and operational efficiency.

Modern low profile floor scales often feature digital indicators that are easy to read and operate. These indicators may include backlit displays for visibility in low-light conditions and additional functions like tare weight and unit conversion.

The platform of a carbon steel floor scale is designed to withstand heavy use and is resistant to wear and tear, ensuring long-term reliability.

Low profile scales offer easier access and space-saving benefits compared to high profile scales, which may be necessary for certain heavy-duty applications.

While stainless steel offers superior corrosion resistance, carbon steel provides strength and durability at a lower cost, making it suitable for many industrial applications.

Digital scales, with their precise readings and user-friendly interfaces, are generally preferred over analog scales, which may be less accurate and harder to read.

Used in warehouses, factories, and production lines for weighing raw materials, finished products, and machinery parts. Essential for quality control and inventory management.

Ideal for environments where hygiene is crucial, such as in the processing and packaging of food products. Easy to sanitize and resistant to rust and contaminants.

Used for precise measurement of ingredients and products in laboratories and production facilities. Stainless steel construction ensures compliance with sanitary and safety regulations.

Facilitates accurate weighing of goods for shipping and receiving, ensuring compliance with transport regulations and optimizing shipping costs.

Provide ongoing training and support for operators responsible for using the truck scale. Ensure they understand proper operating procedures, safety protocols, and troubleshooting techniques to address common issues. Regular training sessions can improve efficiency and reduce the risk of operator errors.

Address any issues free and promptly in one year by repairing or replacing damaged or malfunctioning components. This may include replacing load cells, cables, junction boxes, or electronic parts that are no longer functioning properly(except for natural disasters and man-made damage).

Stay updated with the latest software releases and system upgrades for the truck scale. Install software updates provided by the manufacturer to enhance performance, add new features, or address security vulnerabilities. Consider upgrading the scale's system hardware if needed to meet changing operational requirements.

Maintain service agreements with qualified technicians or service providers 24h remote hotline technical assistance to urgent service requests and provide onsite assistance when needed.

A: Common materials include stainless steel and mild steel, which offer durability and resistance to corrosion. Stainless steel models are preferred in food processing and pharmaceutical industries.

A: Weight capacity can vary widely depending on the model, typically ranging from 1,000 to 20,000 pounds. Check your scale’s specifications for its exact capacity.

A: A low profile design makes it easier to load and unload items, reducing the need for additional equipment like ramps or lifts. This design is space-efficient and improves safety.

A: Ramps are not always necessary but can be very useful in certain situations, such as when using forklifts or pallet jacks to load heavy items onto the scale. They help improve ease of use and safety by providing a smooth transition onto the weighing platform. Ramps can be removable or permanently attached, depending on your needs.

A: Reset procedures vary by model. Generally, you may need to power cycle the scale or use a reset function provided in the user interface. Refer to the user manual for specific instructions.